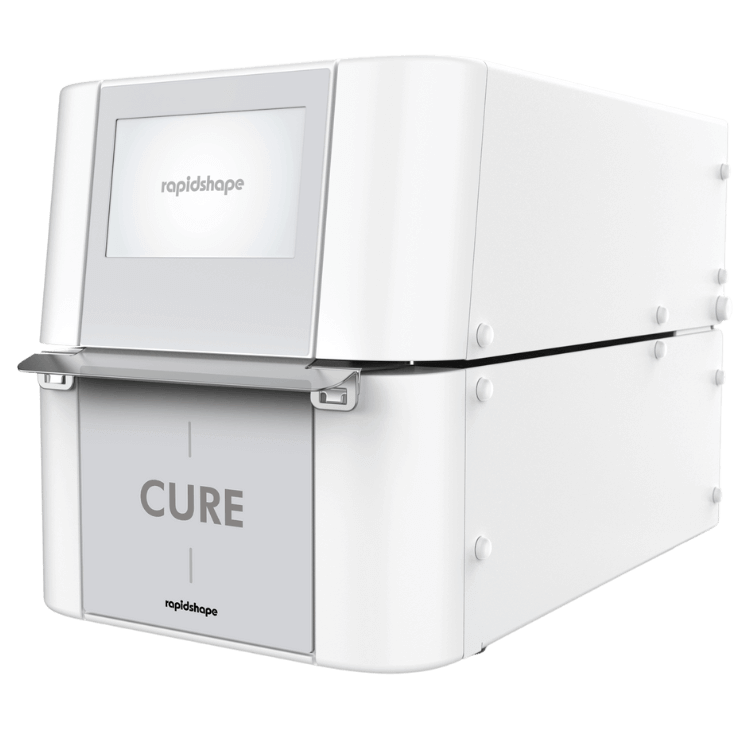

360° Curing at the Touch of a Button

WASH

The WASH automatic cleaning system excels thanks to its simple operation and process controlled connection to your printer, for professional and validated post-processing of your printed parts.

Thanks to automatic selection of the appropriate cleaning program and cleaning medium, cleaning the printed parts is not only process-safe and simple, but also environmentally friendly principle with pre-cleaning and final cleaning. (patent pending)

Cleaning and post exposure with validated parameters to exclude the risk of incorrect processing.

| PERFORMANCE PARAMETERS | CURE |

|---|---|

Cleaning Chamber Volume (W x D x H) | 119 x 160 x 99 mm

|

Cleaning Time | approx 6–8 minutes (depending on material)

|

Cleaning Medium | Isopropanol, ethanol

|

Connections | WiFi/LAN

|

Dimension (W x D x H) | 235 x 464 x 270 mm (w/o Iso Container) |

Version | with vacuum

|

Power Input | 120 W, 24 V DC |

Features

Washing 3D printed parts in just about 6-8 minutes featuring clean handling of sticky resins (patents pending) gets easy by the automatic cleaning unit. The consumption of cleaning agent is reduced to a minimum, while ensuring optimal cleaning results.

The WASH and CURE are seamlessly connected to the corresponding 3D printer to ensure the easiest handling. This allows the cleaning unit to exactly define which cleaning program has to be selected.